Results of High Precision Machining

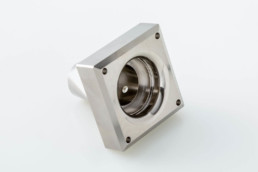

In the field of machinery and equipment, we manufacture not only equipment parts such as R-shape machining, thin-wall machining, and special screws, but also jigs and inspection tools.

In the automotive and aerospace fields, we have processing record including F1 parts, motorcycle brake parts, throttle shafts, jigs and inspection tools in addition to valve parts.

We have received a good reputation for the finish of the tapered and seated surfaces.

We manufacture products in accordance with the customers' requirements while making proposals on cutting technology.

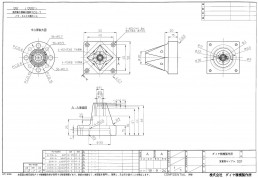

SURFACE GRINDING PROCESS

With surface grinding, a surface pitch of ±0.001 mm is possible. Flatness varies depending on the shape and material, however, we can grind 0.002 mm for a 100 mm square of steel and 0.005 mm for a 200 mm square. (We are also capable of grinding materials such as aluminum, brass, and titanium.)

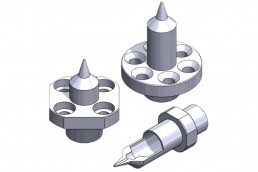

MOLDING PROCESS

FLAT SURFACE PROCESSING

| iron and steel | non-ferrous | |

| 100 square flatness(mm) | 0.002 | 0.005 |

| 200 square flatness(mm) | 0.005 | 0.010 |

3D Shape Processing

Our 5-axis control machining center can handle 3-dimensional processing.

We are equipped with a 3D CAD system, which enables us to process various materials with high accuracy by considering the best processing method, processing conditions and jigs.

Cylindrical grinding

Blade shape processing

As the cylindrical grinding process is an integrated process that includes blank machining, heat treatment, finishing, and surface treatment, we can provide a wide range of materials and shapes with high precision and optimum processing methods. This is an example of a spindle with a surface roughness of 0.4S and runout accuracy of 0.001 mm.