Our precision machining technology is used in the core of equipment that requires extreme precision and high reliability under extreme conditions, such as rockets in the aerospace field and Formula 1 machines that run at speeds of up to 350 kilometers per hour on a race track, and has continued to grow over the years since our founding.

We support further evolution of cutting-edge manufacturing by continuing to explore and challenge new technologies.

We have a wide variety of facility that can handle products of small quantity and large variety for R&D and prototyping.

We can handle everything from development and design to machining, assembly and inspection.

Our experts can provide technical consultation on metal processing based on their years of expertise.

Please feel free to contact with us about complex shapes, slanted/slanting holes, thin wall processing, etc.

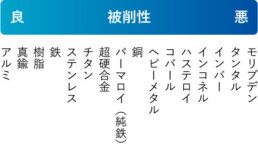

The following are examples of materials that we have processed. Please refer to the following pages for examples.

The degree of difficulty varies depending on the material (good or bad machinability) and shape (thin wall, fine hole, etc.).

Material properties may differ from those shown in the chart due to differences in composition.