As of June 2020

Machine Tool

| Equipment Name | Machine manufacturer | Model | Processing range | Number of machines owned | Note | |

|---|---|---|---|---|---|---|

| 5-axis vertical machining | Mori Seiki | NMV3000 | Processing range | φ350 x 300 | 2 | 34 Palette Number of tools: 121 |

| Horizontal machining | Makino Milling Machine | A-55 | XYZ | 560,560,560 | 1 | 8 pallets Number of tools: 127 |

| CNC JIG BORER | Yasuda Industries, Ltd. | YBM-950V | XYZ | 900,500,350 | 1 | Number of tools: 40 |

| Vertical machining | Makino Milling Machine | V56 | XYZ | 750,350,400 | 3 | Number of tools: 40 |

| Mori Seiki | DV5080 | 800,530,510 | 1 | Number of tools: 30 | ||

| Okuma | MB-46VA | 560,460,460 | 2 | Number of tools: 20 BT40 |

||

| Micro Hole Drilling Machine | DAIYA SEIKI Co., Ltd | BISSIAH ML-10 | Hole diameter | φ0.03 to φ0.3 mm in diameter | 1 | Lathe type |

| BISSIAH XZ | Hole diameter | φ0.03 to φ0.3 mm in diameter | 1 | Moving table type | ||

| Vibration cutting NC lathe | CITIZEN MACHINERY | VC03 | Processing range | φ40×50 | 1 | Number of tools: 5 With low-frequency vibration cutting function |

| NC composite Precision automatic machines |

CITIZEN MACHINERY |

R04 | Processing range per one chuck |

φ4×30 | 2 | Number of tools: 17 |

| F-16 | φ16 x 100 | 1 | Number of tools: 10 | |||

| K-16 | φ16×200 | 1 | Number of tools: 9 and more Back processing |

|||

| A-16 | φ16×40 (RGB) | 1 | Number of tools: 12 and more | |||

| L-20 | φ16×200 | 4 | Number of tools: 10 Back processing |

|||

| M16 V | φ16×320 | 3 | Number of tools: 18 and more Back processing, Y-axis function |

|||

| M20 V type | φ20×320 | 3 | Number of tools: 18 and more Back processing, Y-axis function |

|||

| M32 V type | φ32×320 | 4 | Number of tools: 18 and more Back processing, Y-axis function |

|||

| E32 (K,E2,E3) | 各1 | Number of tools: 20 (Back processing, Y-axis function) |

||||

| CNC composit lathe | Miyano | BND51 | Processing range | φ51×320 | 1 | Number of tools: 12 (can be added) Back processing |

| MAZAK | INTEGREX200-III | φ300×450 | 1 | Number of tools: 40 | ||

| Mori Seiki | NL2000SY | φ300×450 | 1 | Number of tools: 40 | ||

| CNC lathe | MAZAK | QT 6T | Maximum Machining diameter processing length |

φ130 x 200 | 4 | Number of tools: 8 |

| QT 8 | φ100×200 | 1 | Number of tools: 8 | |||

| QT 20 | φ200 x 270 | 1 | Number of tools: 8 | |||

| SQT 200MY | φ300×540 | 1 | Number of tools: 12 With rotating tool |

|||

| QT 30 (650) | φ320×550 | 1 | Number of tools: 8 | |||

| QT 30N (1000) | φ320×900 | 1 | Number of tools: 8 | |||

| QTS 200 | φ250×500 | 2 | Number of tools: 12 | |||

| NC milling machine | SHIZUOKA MACHINE TOOL | VHR-AP | XYZ | 700,320,400 | 1 | 2 axis NC |

| OKUMA & HOWA | RANCON 40 | 580,410,400 | 1 | |||

| Slotting machine | Iwashita Industrial | IH2002 | XYZ | 200,200,200 | 2 | (NH2 700 X 300 X 400) |

| Jig borer | HAUSER | 3 BA | XY | 400,250 | 2 | |

| Jig grinder | HAUSER | 3 SM | XY | 400,250 | 1 | |

| MOORE | 18型 | 460,250 | 1 | |||

| Gun drill | MARUEI | GDM-120 | Hole diameter and stroke | φ1 - φ6 mm dia. x 100 mm | 1 | |

| Surface grinding machine | NAGASHIMA SEIKO | NP 415-F | XYZ | 550,190,500 | 1 | |

| NX 420-M1 | 600,200,500 | 1 | ||||

| OKAMOTO | PFG 500 DXAL II | 600,140,300 | 1 | |||

| AMADA | TECHSTER 84 | 800,400,100 | 1 | NC | ||

| CNC cylindrical grinder | STUDER | S31 | Outer and inner diameter | φ340 x 650 | 1 | With 2-axis NC Internal grinding function |

| TSUGAMI | G30 | Special purpose machine for chuck work | 1 | 2 axis NC | ||

| Cylindrical grinding machine | KONDO | UGK 450 | Outer and inner diameter | φ150×450 | 1 | Equipped with an internal grinding function |

| High Gloss 450 | Outer and inner diameter | φ150×450 | 3 | 2 units with internal grinding function | ||

| High Gloss 250 | Outer diameter | φ150×250 | 1 | |||

| CGK 250 | Outer diameter | φ150×250 | 4 | |||

| OKAMOTO | OGM-250 | Outer diameter | φ200×500 | 1 | ||

| TSUGAMI | GU-25 | Outer and inner diameter | φ80×250, φ7-40 | 1 | Equipped with an internal grinding function | |

| MARUEI | HGM-120C | Outer diameter | φ50×120 | 1 | with a loader Dedicated machine for chuck production |

|

| Toyoda Seiko | G32 | Outer and inner diameter | φ220 x 500 | 1 | Equipped with an internal grinding function | |

| Shigiya Seiki | GPH-30B | Outer and inner diameter | φ300×1000 | 1 | With CNC Internal grinding device | |

| Taiyo Koki | CGN20/15 | Outer diameter | φ200×175 | 1 | With CNC Sizing Device | |

| CGN25/60 | Outer diameter | φ250×280 | 2 | With CNC sizing device With conveyor |

||

| Small internal grinding machine | SII | STG-3S | Hole diameter and stroke | φ0.7 to 15 in diameter, 1 to 25 mm | 4 | Maximum speed: 150,000 rpm |

| STG-3N,6N | 8 | |||||

| Internal grinding machine | OKAMOTO | IGM-15EX | Hole diameter and stroke | φ6 - 150 mm dia. x 100 mm | 1 | |

| IGM-2M/MB | φ6 - 200 mm dia. x 100 mm | 7 | ||||

| Taiyo Koki | IGH-2NT | φ3 - 200 x 150 mm | 2 | CNC Swivel Angle 30 Degrees | ||

| IGV-3NT | φ7 - 200 x 150 mm | 1 | ||||

| Center grinding machine | Vanno-Seiki | SCGM-250A, 500A | Hole diameter and stroke | φ50×250,500 | 3 | |

| Universal grinding machine | CITIZEN | TG-2 | 1 | |||

| TG-3 | 8 | |||||

| Thread grinding machine | Drake Mfg. | TE-LM 200 | Processing range | φ200×330 | 1 | |

| Taiyo Koki | CGN25/30 | Processing range | φ250×280 | 1 | With conveyor | |

| NC electrical discharge machine | Mitsubishi Electric | EA8PV | 350,250,350 | 1 | ATC19本 | |

| EA12V | 300,250,250 | 2 | ATC19本 | |||

| Wire cut Electric Discharge machine |

FANUC | Robocut Alpha-0iA | XYZ | 320,220,180 | 1 | |

| Robocut Alpha-1C | 520,370,180 | 1 | ||||

| Robocut Alpha-1iC | 520,370,180 | 1 | ||||

| W2 | 350,500,250 | 1 | ||||

| brother | HS-3600 | 300,200,150 | 1 | |||

| Mitsubishi Electric | NA2400 | 600,400,310 | 1 | indexed | ||

| MV2400R | 1050,820,305 | 1 | ||||

| MV1200 | 400,300,220 | 2 | ||||

| BA24 | 600,400,310 | 2 | indexed | |||

| BA8 | 320,250,220 | 1 | ||||

Other machine tools

| Engine lathe, bench lathe | (Tsugami, Katsukura) | 30台 |

| Vertical/Horizontal milling machine | (MAKINO, etc.) | 17台 |

| Drilling machines and tapping machine | (ASHINA, etc.) | 21台 |

| Air blast machine | NICCHU | 3台 |

| Ultrasonic cleaning device | (KYOWA IRIKA) | 5台 |

| Laser marker | (SUNX, KEYENCE) | 2台 |

| Mirror finishing machine | (Nippon Speed Shore, etc.) | 2台 |

| Precision Cutting Machine | (Heiwa Technica) | 1台 |

| Gear cutting machine (#120) | (HAMAI) | 2台 |

| Honing machine | (FUJI, etc.) | 5台 |

| High-frequency induction heating machine | (SPC ELECTRONICS, etc.) | 5台 |

| Salt bath quenching furnace | 1台 | |

| High-temperature tempering furnace | (THERMAL) | 2台 |

| TIG pulse welding machine | (DAIHEN) | 1台 |

Testing and measurement instruments

| Equipment Name | Equipment manufacturer | Model | Measurement range | Number of machines owned | Note |

|---|---|---|---|---|---|

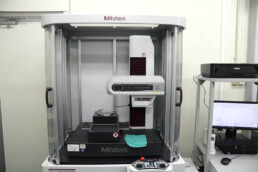

| 3D Measuring Machine | Mitutoyo | CRYSTA-Apex S574 | XYZ axes: 500, 700, 400 | 2 | MPEp |

| Max. loading weight: 180kg | MPEp=(1.9+3L/1000)μm | ||||

| High-precision contouring and Surface roughness measuring instrument |

Mitutoyo | Form Tracer Extreme CS-H5000CNC |

X-axis (horizontal): 200mm | 1 | Measuring force: 4mN (constant) |

| Z-axis (vertical): 12 mm | |||||

| Mahr | MERCERF LD 120 | X-axis (horisontal) 120 | 1 | X-axis measuring point distance 0.25 μm | |

| Z-axis (longitudinal direction) 10 | Z-axis resolution 8nm | ||||

| Measurement pressure 0.5mN to 50mN | |||||

| Roundness and cylindrical form measuring machine | Tokyo Seimitsu | RONDCOM43C | Maximum measuring diameter 250 | 1 | Measuring Geometric Tolerance |

| Roundness, concentricity, and coaxialty | |||||

| Mitutoyo | RA-2200CNC | Maximum measurement height 300 | Squareness, flatness, cylindricity | ||

| (CNC) | |||||

| Surface roughness measuring instrument | Mitutoyo | SURF TEST SV-3100S4 | Resolution 0.01μm (800μm range) |

1 | Cross-sectional curves, roughness curves, and Various parameters by waviness curve, etc. |

| X-axis 100 | |||||

| Z-axis 300 (motorized) | |||||

| Body weight 140kg | |||||

| SJ-410 | Measurement range 50mm | 1 | Measuring force 0.75mN | ||

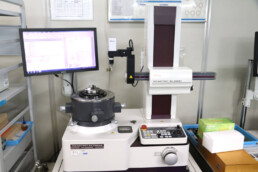

| Micro hardness tester (Micro-Vickers) |

MATSUZAWA | MXT 30 | Microscopic stage size | 1 | Test Load[g] |

| Width x Height: 100 x 100 | 10, 25, 50, 100, 200, 300, 500, 1000 | ||||

| Measuring height: 85 | (Dial switching system) | ||||

| Rockwell hardness tester | MATSUZAWA | MBK-E type | Measuring height: 200, Depth: 130 |

1 | Test Load[kg]: 60, 100, 150 |

| Microhite | TESA | Micro-hite plus M600 | Measurement range: 600 | 3 | |

| Measuring microscope | Mitutoyo | MF-A2010C | XY axes: 200, 100 | 2 | With Qm-Data200 |

| Measuring microscope | KEYENCE | IM-7000 | XY axis: 200, 200, Measurement height: 75 |

1 | With light probe measurement function |

CAD/CAM systems

| Equipment Name | Equipment manufacturer | Model | Number of machines owned | Note |

|---|---|---|---|---|

| CAD system | Solid Works | Solid Works | 1 | |

| CoCreate Software | ME10 | 10 | 3D: 1 unit included | |

| CAM system | JBM | Master Mill Level 5 | 1 | |

| TACTX | Win MAX | 2 |

Washing equipment

| Equipment Name | Equipment manufacturer | Model | Number of machines owned | Note |

|---|---|---|---|---|

| Hydrocarbon Vacuum Cleaning and Drying Machine | CLEANVY | CLOVA-4030 | 1 | One-bath fully automation |

| Three-tank washing and drying machine | CLEANVY | FW2-3040 | 1 |

As of June 2020