Desktop-sized micro hole drilling machine, BISSIAH XZ150

Challenging the limits of micro hole machining

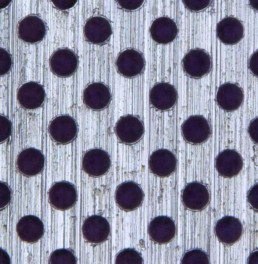

The micro hole drilling machine BISSIAH XZ150 uses the latest developed technology based on the micro drilling technique cultivated for the lathe type micro hole drilling machine, BISSIAH ML10. This desktop-sized drilling machine enables the drilling of many holes in a plate or a similar workpiece.

The drilling spindles are equipped with high-sensitivity process (reaction) force sensors to detect the stress of the drill of φ0.02-0.3 mm in diameter. The sensors simultaneously detect the torque which is the force in the direction of twisting, and the thrust force which is the force in the direction of pressing back. They feed back the detected forces to the control system of the BISSIAH in real time.

For example, you can imagine easily that a thin drill 0.05 mm in diameter, which is about half the diameter of a human hair, is very fragile even against a delicate force. By detecting such a delicate force, BISSIAH enables you to drill a micro hone deeply even in a "hard to process" material.

Features of BISSIAH

- Equipped with two spindles; the center hole drilling spindle and the micro hole drilling spindle, to reduce the frequency of tool changes

- Supported by the in-house developed aerostatic bearings, each spindles keep the run-out within 100 nanometers.

- The XY table oriented vertically for easy discharge of the chips. Maximum processing range: 150 mm(100mm when both spindles are used simultaneously).

- The least input increment of the XY table is 1 μm. Mounting the linear scale fully closed for high precision control.

- The leading edge position of the tool automatically detected with the thrust force sensor

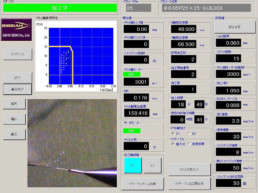

- Easy input of machine operation, drilling conditions, and drilling location at the LCD touch screen

- Two CCD cameras to display an enlarged view of the drilling area

- Semi-dried machining with automatic spraying of cutting oil: minimizing scattering of cutting oil by fully covering the machining area.

- Provide the processing conditions and parameters with various materials (optional).

Technical data of BISSIAH

| Micro hole drilling spindle | Bearing structure | Aerostatic bearing |

| Revolution Speed | 200 to 4,000 rpm | |

| Maximum Torque | 0.06 Nm | |

| Processing force feedback | 2 axes (torque sensor and thrust sensor) | |

| Center hole drilling spindle | Bearing structure | Aerostatic bearing |

| Revolution Speed | 200 to 4,000 rpm | |

| Maximum Torque | 0.19 Nm | |

| Processing force feedback | 1 axis (Thrust sensor) | |

| Drill unit and axis | resolution | 1 μm |

| Moving range | 150㎜ | |

| Feed speed | Max.600 mm/min | |

| Workpiece table X-axis (horizontal axis) | resolution | 1 μm |

| Maximum movement range | 160㎜ | |

| Actual processing range | 100 mm (when 2 spindles are used) | |

| Actual processing range | 130 mm (when 1 spindle is used) | |

| Feed speed | Max. 1,000 mm/min | |

| Workpiece table: Y-axis (vertical axis) | resolution | 1 μm |

| Maximum movement range | 160㎜ | |

| Actual processing range | 150㎜ | |

| Feed speed | Max. 1,000 mm/min | |

| Air supply | Air pressure | 0.6 to 1MPa |

| Maximum air consumption | 100 L/min | |

| Machine spec | W x D x H | 1,000 x 780 x 1,500 mm |

| Weight | 950 kg | |

| Control | Machine control | PLC |

| X/Y AXIS CONTROL | Fully closed loop control | |

| Screen display control | Personal computer (OS: Windows7) | |

| Display and input features | Display and input | 15-inch touch screen display |

| Processing video camera | 300K pixels 1/4-inch CCD CAMERA | |

| Processing data registration features | Processing conditions | MAX.1,000件 |

| Table position coordinates | MAX.10,000件 |